General Electric GEnx

From Wikipedia, the free encyclopedia

The General Electric GEnx (General Electric Next-generation) is an advanced dual rotor, axial flow, high-bypass turbofan jet engine in production by GE Aviation for the Boeing 787 and 747-8. The GEnx is intended to replace the CF6 in GE's product line.

Contents

[hide]

Development[edit]

GEnx on 747-8I prototype

GEnx on 747-8I prototype

The GEnx and the Rolls-Royce Trent 1000 were selected by Boeing following a run-off between the three big engine manufacturers. The GEnx uses some technology from the GE90 turbofan, including composite fan blades, and the smaller core featured in earlier variants of the engine. The engine carries composite technology into the fan case.

Both engine types will have a standard interface with the aircraft, allowing any Boeing 787 to be fitted with either GE or RR engines at any time.[1][2] The engine market for the 787 is estimated at US$40 billion over the next 25 years. A first is the elimination of bleed air systems using high temperature/high pressure air from the propulsion engines to power aircraft systems such as the starting, air-conditioning and anti-ice systems. Both engines enable the move towards the More Electric Aircraft, that is, the concept of replacing previously hydraulic and pneumatic systems with electrical ones to reduce weight, increase efficiency, and reduce maintenance requirements.

The GEnx was expected to produce thrust from 53,000 to 75,000 lbf (240 to 330 kN) with first tests commencing in 2006 and service entry by 2008 (delayed by 787 deliveries). Boeing predicts reduced fuel consumption of up to 20% and significantly quieter engines than current turbofans. A 66,500 lbf (296 kN) thrust version (GEnx-2B67) will be used on the 747-8. Unlike the initial version, for the 787, this version has a traditional bleed air system to power internal pneumatic and ventilation systems. It will also have a smaller overall diameter than the initial model to accommodate installation on the 747.

General Electric began initial test runs of the bleedless GEnx variant on 19 March 2006.[3] The first flight with one of these engines took place on 22 February 2007, using a Boeing 747-100, fitted with one GEnx engine in the number 2 (inboard left hand side) position.

Operational history[edit]

Introduced in late 2011 on a 747-8 freighter, Cargolux surpassed one million flight hours in early 2017.[4] In the summer of 2012, three engines suffered Low Pressure Turbine (LPT) failures. One failure was caused by an assembly problem, which led to inspections of all other engines then in service.[5]

During the spring and summer of 2013, GE learned of four 747-8F freighters that suffered icing in their engines at altitudes of 40,000 feet and above. The most serious incident involved an AirBridge Cargofreighter; on July 31, while at an altitude of 41,000 feet over China, the flight crew noted two engines surging while a third lost substantial power. The pilots were able to land the plane safely but the engines were found to have sustained damage. Among the possible factors cited was "'unique convective weather systems' such as unusually large thunderstorms reaching high altitudes." Boeing is working with GE on software solutions to the problem.[6] Altitude was restricted until GE changed the software to detect the high-altitude ice crystals and opens bleed air valve doors to eject them before they enter the core.[4]

In January 2016 a Japan Airlines 787 had an inflight shutdown after flying through icing conditions, caused by ice formed on fan blades and ingested: the blades moved forward slightly and rubbed on the abradable seal in the casing.[4] In March 2016, the US FAA ordered emergency fixes on the GEnX-1B PIP2.[7] The airworthiness directive affects 43 Boeing 787 Dreamliners in the US.[8] Abradable material in the casing in front of the fan blades was ground to keep them from rubbing when ingesting ice or debris on 330 GEnx PIP-2.[4]

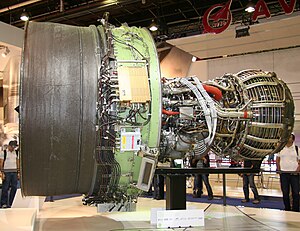

Fan blades and inlet guide vanes of GEnx-2B

Fan blades and inlet guide vanes of GEnx-2B Detail of GEnx core

Detail of GEnx core

The GEnx is derived from the GE90, but features a number of weight-saving features:

Fan diameter of 111 in (2.8 m) for the 787-8 and 105 in (2.7 m) for the 747-8.

Composite fan blades with steel alloy leading edges.

Fan case of composite material which reduces weight and thermal expansion.

Titanium aluminide stage 6 and 7 low-pressure turbine blades.

Fuel burn reduction technologies include:

Fan bypass ratio of 9.6:1, which also helps reduce noise.

High-pressure compressor based on GE90-94B, with 23:1 pressure ratio and only 10 stages. Also, shrouded guide vanes reduce secondary flows.

Counter-rotating spools for the reaction turbines to reduce load on guide vanes.

Lean TAPS (twin annular premixed swirler) combustor to reduce environmentally-harmful emissions with improved airflow to prevent the flame to flash back.[9]

Among features to reduce maintenance cost and increase engine life are:

Spools with lower parts count achieved by using blisks in some stages and low blade counts in other stages and by using a low number of stages.

Internal engine temperatures reduced by using more efficient cooling techniques.

Debris extraction within the low-pressure compressor guards high-pressure compressor.

All of these yield a fuel burn said to be 15% better than GE's CF6-80C2 engines for widebody aircraft.

Applications[edit]

Specifications[edit]

This engine is a dual rotor, axial flow, high bypass ratio turbofan. The 10-stage high-pressure compressor is driven clockwise (Aft Looking Forward) by a 2-stage high-pressure turbine. The single-stage fan and 4-stage low-pressure compressor are driven counterclockwise (Aft Looking Forward) by a 7-stage low-pressure turbine. The engine control system includes a Full Authority Digital Engine Control (FADEC), which has an aircraft connection for digital communication. An engine monitoring unit (EMU) provides vibration level signals to the aircraft.

GEnx specifications[10][11]Engine

version | Arrangement | Performance | Dimensions (inch)

and Weight (lb) | Certified

(FAA) | Application | Entry Into Service |

Fan

diameter

(in) | Fan | LPC | HPC | LPT | HPT | Thrust max

(lbf) | Flat-Rated Temp C | Overall

Pressure Ratio

(OPR) | Fan

Bypass Ratio

(BPR) | Air flow

(kg/s) | SFC

(max power) | T/W

ratio | Length | Max Envelope | Weight

(Dry) |

Take-off

(5 min) | Max

Cont. | Take-off | Max

Cont. | Width | Height |

| -1B54 | 111 | 1 | 4 | 10 | 7 | 2 | 57,400 | 56,300 | ISA+15 | ISA+10 | 36.0 |

|

|

| 4.48 | 194.0 | 139.0 | 137.0 | 12,822 | Mar 31, 2008 | B787-3 |

|

| -1B58 | 111 | 1 | 4 | 10 | 7 | 2 | 61,000 | 56,300 | ISA+15 | ISA+10 |

|

|

|

| 4.76 | 194.0 | 139.0 | 137.0 | 12,822 | Mar 31, 2008 | B787-3,-8 |

|

| -1B64 | 111 | 1 | 4 | 10 | 7 | 2 | 67,500 | 61,500 | ISA+15 | ISA+10 | 41.0 |

|

|

| 5.23 | 194.0 | 139.0 | 137.0 | 12,822 | Mar 31, 2008 | B787-8,-9 |

|

| -1B67 | 111 | 1 | 4 | 10 | 7 | 2 | 69,400 | 61,500 | ISA+15 | ISA+10 | 43.0 |

|

|

| 5.41 | 194.0 | 139.0 | 137.0 | 12,822 | Mar 31, 2008 | B787-8,-9 |

|

| -1B70 | 111 | 1 | 4 | 10 | 7 | 2 | 72,300 | 66,500 | ISA+15 | ISA+10 | 43.0 | 9.6:1 |

|

| 5.64 | 194.0 | 139.0 | 137.0 | 12,822 | Mar 31, 2008 | B787-8,-9,-10 |

|

| -2B67 | 105 | 1 | 3 | 10 | 6 | 2 | 67,400 | 58,500 |

|

| 43.0 | 8.6:1 |

|

| 5.44 | 185.0 | 127.0 | 127.0 | 12,400 | July 22, 2010 | B747-8 |

|

Notes:

Data for sea level static, standard pressure, no customer bleed or customer horsepower extraction, ideal inlet, 100% ram recovery, production aircraft flight cowling, production instrumentation, fuel lower heating value of 18,400 BTU/lb.

The 787-3 variant was cancelled in December 2010 due to low demand by customers.[12]

Specifications (GEnx-1B64)[edit]

Rear view of a GEnx-1B on a Jetstar 787-8, showing noise-reducing chevrons

Rear view of a GEnx-1B on a Jetstar 787-8, showing noise-reducing chevrons

Data from [13]

General characteristics

Type: Turbofan

Length: 4.69 m (184.7 in)

Diameter: 2.82 m (111.1 in)

Dry weight: 5,816 kg (12,822 lb)

Components

Compressor: Axial, 1 stage fan, 4 stage low pressure compressor, 10 stage high pressure compressor

Combustors: Annular

Turbine: Axial, 2 stage high pressure turbine, 7 stage low pressure turbine

Performance

See also[edit]

References[edit]

Jump up^ "Boeing 787 Aircraft Facts, Dates and History". Flightlevel350.com. Retrieved 2013-05-09.

Jump up^ "Boeing 787 Dreamliner Long-Range, Mid-Size Airliner". Aerospace Technology. Retrieved 2013-05-09.[unreliable source?]

Jump up^ "General Electric Performs First Run of New GEnx Engine." Flight International. 21 March 2006.

^ Jump up to:a b c d Sean Broderick (Aug 31, 2017). "Issues With Newest Engines Provide Early MRO-Proving Opportunities". Aviation Week Network.

Jump up^ "GE identifies installation issue in GEnx, orders inspections". Flightglobal. Retrieved 6 October 2012.

Jump up^ Pasztor, Andy (October 16, 2013). "Icing Hazards Surface on Boeing's Newest 747 Jet". Wall Street Journal. p. B3. Retrieved June 10, 2014.

Jump up^ "FAA orders engine icing fixes for GEnx-powered Boeing 787 Dreamliners". Aviation Safety Network. 2016-04-23.

Jump up^ Patterson, Thom (April 23, 2016). "FAA Orders Urgent Fixes For Boeing 787 Dreamliners". CNN.

Jump up^ General Electric (June 2013). "TAPS II Combustor Final Report" (PDF). Continuous Lower Energy, Emissions and Noise (CLEEN) Program. FAA.

Jump up^ FAA TCDS E00078NE

Jump up^ "GE plans mid-July nod for GEnx siblings." Flight International. 16 June 2010

Jump up^ "Boeing raises aircraft prices 5.2%, cancels short-haul 787". Seattle Times. 13 December 2010.

Jump up^ Gas Turbine Engines. Aviation Week & Space Technology Source Book 2009. p. 118.

External links[edit]